Subsea installation and maintenance of valves is an essential operation in off shore energy project where the precision tool must be capable of operating in hostile waters and conduct. Water based under sea equipment solutions is what we do at Seaward Tech based company and it is here that we come with the advanced under sea torque wrenches that are built using an efficient and proper process of joining valves that are under water. In the following ways, these special tools are significant in subsea operations.

Ensuring Precise Torque Application

The way underwater torque wrenches are constructed is such that, it exerts measured torque across bolts and fasteners along the installation or repair of valves in water. Preciseness of torque to less than 10nNm is essential to avoid leak and provide the secondary strength of the system and maintained sustainable reliability of the subsea system. Our tools are metered to operate in deep water conditions and eliminates guess work and over or under-tightening.

Enabling Remote and Diverless Operations

It is expensive and risky to intervene in a deep-water setting with manual interventions. Our under water torque wrenches have the possibility of being driven or connected to ROVs (Remotely Operated Vehicles) valve assembly and maintenance can be worked on by divers. This feature greatly decreases operations risk and expenses and boosts efficiency.

Compatibility with Subsea Valve Systems

Our torque wrenches are designed to suit assorted types of valves; our torque wrenches are designed to suit a range of valves (ball valves, gate valves, choke valves, etc.) as well as different bolts and torque settings. The same versatility gives them an unparalleled role in the subsea construction and repair.

Enhancing Safety and Reducing Downtime

Applying torque manually is time consuming and subject to error when done underwater. Torque wrench is either automated, or hydraulically assisted, to limit waste in assembly by increasing speed and ensuring a high level of consistency. This saves down time due to installation or emergency repairs so offshore operations remain on schedule.

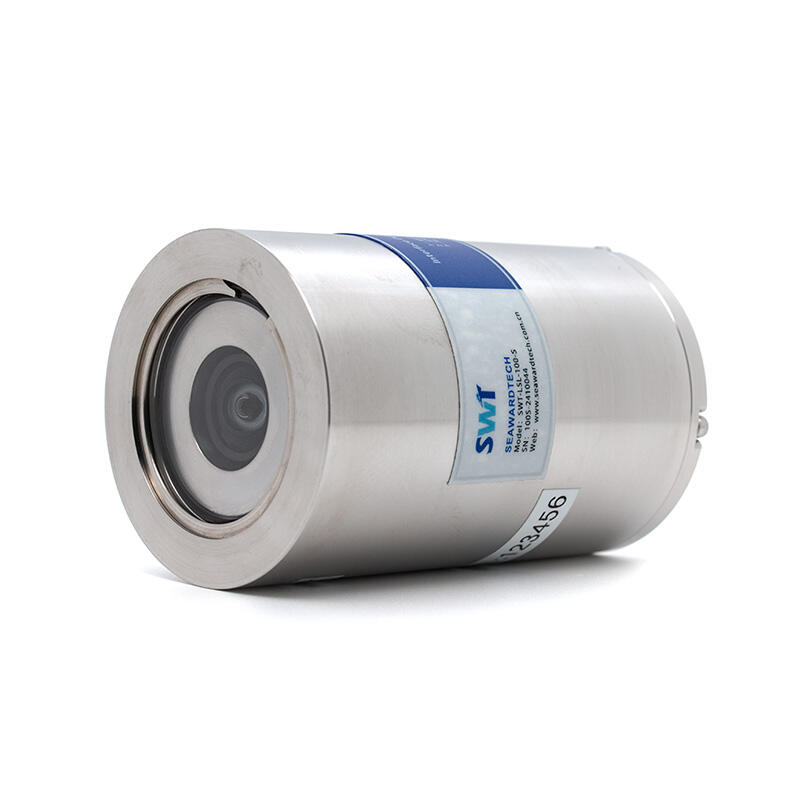

Corrosion-Resistant and Durable Design

Subsea equipment requires high pressure, salt water corrosion and high temperatures. Our meticulous design using stainless steel and corrosion protective coating allows our torque wrenches to last the duration in punishing subsea environments.

Supporting Preventive Maintenance Programs

Proper valve maintenance in the subsea pipeline and wellhead is important in the avoidance of valve failures. Torque wrenches used underwater enable the performer to conduct a regular check and adjustments without retrieving the equipment to the service, promoting service life and reducing the disruption.

Conclusion

The use of the underwater torque wrenches in the assembly of subsea valves prove to be a central element of precision and efficiency and safety of underwater processes in the offshore energy sector. Our torque solutions are effective and sturdy to serve the needs of deep-water projects.