The offshore engineering is a dynamic profession where there is no compromise on precision and reliability. Whether it is the exploration of the deep sea, maintenance of subsea infrastructure or oceanic research, the success depends on devices that work perfectly even under extreme pressure, both literal and operational. Underwater torque wrenches are the most crucial of them as they are important to provide safe fastening of bolts, functioning of a valve, and structural assembly of products that directly determine the safety and efficiency. We have ensured that we are leading the pack in deep-sea innovation at Seaward (Shanghai Weihai Ocean Technology). In our philosophy of “Ever Evolving, we constantly monitor, innovate and incorporate the new technology of underwater torque wrench to ensure compliance to the current needs of the present projects in the offshore industry. The main trends that are contributing to this critical tool category and making the future of subsea operations can be discussed below.

Integration with Subsea Observation and Communication Systems

The transformation of the standalone torque tools into the networked, intelligent systems is a paradigm change. The underwater torque wrenches of today are not isolated but are integrated components of an undersea ecosystem, which also includes observation, communication and control. In Seaward this development is in harmony with our strong points of Observation and Communication. Now the modern torque wrenches can operate in time with high definition underwater cameras including our Goblin Shark 6000 HD Camera and sophisticated real-time data transmission modules. This can be integrated to enable operators to visually verify the alignment of bolts and the engagement of torque in-vitro and simultaneously relay live torque measurements (applied force, rotational speed, and fastener tightness) to surface control centers. The outcome is a new performance of operational accuracy and confidence even in the in-dark, high pressure where visibility and feedback is very sensitive. Combining torque operation with subsea observation and communication, we are bidding adieu to the dangers of misalignment, over-torque and mechanical failure, and assist offshore teams in obtaining safer, faster, and more dependable results.

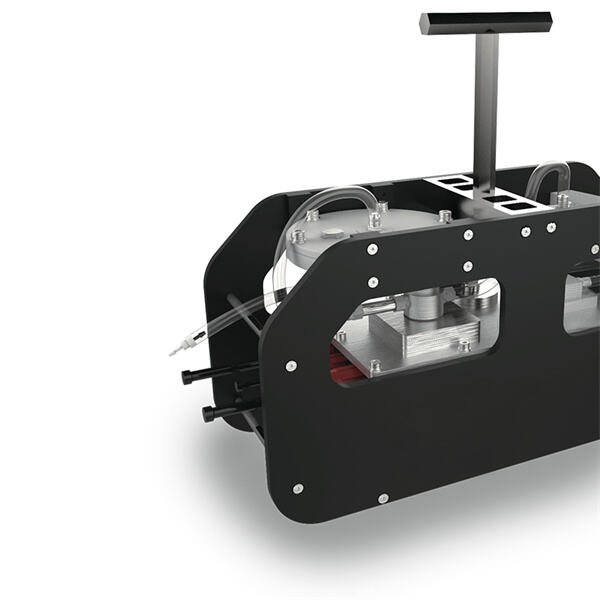

Modularity for Customized Offshore Scenarios

Offshore initiatives differ in magnitude and intricacy such as microbial sampling delicacy and sub sea infrastructure support. We have appreciated the fact that each operation is unique and have adopted the modular design philosophy which is the point of reference that aids the definition of our Customized product segment. The next generation torque wrenches have removable modules that can be customized to particular missions. Operators can: Change deep or ultra-deep depth ratings. Adjust torque values of accurate sampling tools or strong industrial bolts. Restructure interfaces to fit in with the established subsea systems and manipulators. Such modularity not only helps to increase flexibility but also to simplify logistics and lowers the total costs of equipment. One, flexible wrench system can now substitute a variety of specialized tools- making deployment, maintenance and inventory control easier across a variety of offshore missions.

Sustainability-Focused Design

Sustainability is no longer the marginal issue, it is at the center of our design and operation patterns. As part of our Environment and Sustainability interest, and our continual presence in international ocean technology events like the 2025 Ocean Business exhibition at Southampton we are leading in being green in our underwater torque wrench engineering design. Within our sustainability-oriented innovations, there are: Power systems efficient in energy that offer prolonged operational life without consuming much energy, which is essential on battery operated undersea tools. Biofouling- and corrosion-resistant materials that significantly increase the service life and thereby, the lack of frequent replacements and vessel trips. Waterproof, low maintenance designs, less harmful to the environment and will not release debris into vulnerable marine environments. The overall result of increasing the life span of the tools, as well as enhancing their energy efficiency is not only to reduce carbon footprints of its operations, but also to contribute to the global responsibility of a good steward of the ocean.

Concluding Thoughts

Since offshore operations are being extended into more difficult and deeper waters, the tools that will be used to sustain them have to follow suit. The future of the underwater torque wrench technology is in the continuity of seamless connectivity, mission specific modularity and responsible sustainable design. At Seaward, our evolution in this direction is the underwater torque wrench, which reflects our mastery of the deep-sea observation, communications, and tailor-made business environment, and enhances sustainability throughout the industry. Our vision is that together through our innovativeness and environmental consciousness, we will be able to enable the offshore operators to be safer, smarter and more sustainable- the next generation of subsea engineering excellence.